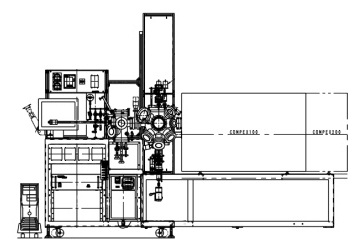

Mobile Combi-Laser MBE

MC-LMBE

Combinatorial research and development by a compact, high performance, and fully PC controlled system

The main body of the system is a UHV laser MBE apparatus to deposit thin films on a substrate by the laser ablation of targets. An excimer or other pulsed laser is irradiated from outside of the UHV chamber via synthesized quartz window. Using two combinatorial masks and a scanning RHEED device, the system enables to prepare many samples at one time, each of them is controlled atomically and has a different growth condition , using a combinatorial mask and targets irradiated by a laser in a high vacuum. The concept of the combinatorial film deposition is a systematic change of growth condition resulted by dividing a substrate by masking into many small regions having different growth parameters each other. This contributes to outstandingly rapid screening of growth conditions. A load-lock transfer component that is a standard equipment of our MC-LMBE makes exchange of targets and substrates very easy.