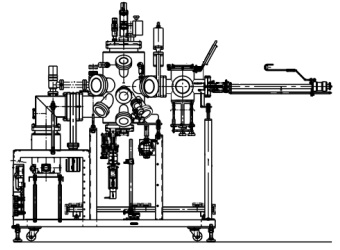

Compact Laser MBE

PAC-LMBE

Our design priority, easy-to-use, brings better controllability of film growth condition

This system is designed to deposit thin films on a substrate by the laser abrasion of target materials in an ultrahigh vacuum(UHV). The apparatus consists of a deposition chamber,an infra-red heating lamp, a target revolution mechanism,and a RHEED chamber. All of them are UHV compatible. An Infra-red lamp heating that featured our appatatus can bring a substrate temperature more than 800℃ and afford to deposit even in a high oxygen partial pressure of higher than 500 mTorr. Standard equipped load-lock transfar mechanism enable to keep deposition environment clean and bring easy-to-use.